6/22/14: Bilge Bulkhead, Tanks, Compression Posts

With the engine area rebuilt, and the engine back on its mounts, it was time to consider installing the bulkhead that separates the bilge area from the tanks area. The photo below shows a random-orbital sander on the bottom of the bilge. The new bulkhead will be installed just aft of the small bulkhead seen in the photo. (This small bulkhead will serve as a form while building the keel area up to its original height.)

A pattern for the new bulkhead was constructed in the usual way, as shown below.

The new bulkhead was cut from 3/4″ Okume. The following photo shows the bulkhead and some of the layers of fiberglass that will cover both sides of the bulkhead.

Next, the fiberglass was applied to both sides of the bulkhead and left to dry. Each side received one layer of biaxial cloth and one layer of unidirectional cloth.

The top of the following photo shows the new bulkhead, which was bonded with fillets of thickened epoxy, then tabbed with three layers of biaxial cloth along each seam. The space between the two bulkheads seen here is where the aft water tank was located. Damaged concrete was removed from this area, so this area is being repaired by building up with a combination of wood, epoxy, and a sand/epoxy paste.

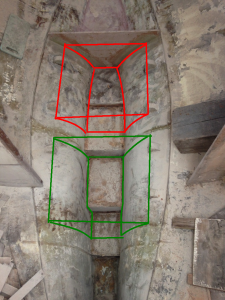

Meanwhile, serious consideration was given to the question of tanks. It was decided that integral tanks will be built. The following photo was taken during earlier stages of the project. Rough outlines of potential forward (red) and aft (green) tanks have been added. One tank will be the holding tank, while the other will be the freshwater tank. The capacities of each tank will be measured before deciding which one is which.

Each tank will have six sides, then internal baffles. Five sides are preexisting parts of the boat: the top of the keel, the starboard hull, the port hull, and two bulkheads. The photo below shows the pattern for the top (the sixth side) of the forward tank. The top will tilt slightly aft to allow drainage of any water that finds its way under the floors.

The top of the forwrd tank was cut from 3/8-inch Okume. This plywood will be built up on both sides by layers of fiberglass.

Next, the top was test-fitted.

To facilitate both installation and maintenance, a large inspection port was cut out of the top. The jig saw was used, then the router was used to clean up the perimeter.

Subsequent posts will cover the continued construction and installation of the top of the holding tank. Before installing the top, however, the other sides of the tank must be prepared. These sides will be covered with layers of biaxial cloth, with tabbing along the corners. The goal, of course, is a strong, completely impenetrable barrier between the contents of the tank and the rest of the boat.

The following photo shows the tops of the keel in the forward tank. These have been covered with thick layers of the epoxy/sand paste, then doused with straight epoxy. the concrete keel is now protected from water from above. This protection will increase further as the tanks are built.

The sides of the tank will be covered with two layers of fiberglass cloth and two layers of tabbing along the seams: cloth, tabbing, cloth, tabbing.

The first layer of fiberglass was wetted out in place, rather than in advance. Large pieces are easy to fit into place while dry, but is difficult to work the resin into the cloth.

Plastic sheets cover the workbench while wetting out cloth in the workshop. The roll of plastic in the photo below is actually a very long tube of plastic, which was designed to be cut into sections and used to cover the slings of a Marine Travelift. This large roll might be enough for the entire restoration project.

The next layer of fiberglass and the two layers of tabbing were wetted out in the workshop.

The following photo shows the inside of the forward tank after two layers of glass and two layers of tabbing have been applied. These bulkheads were installed with three layers of tabbing, so a total of five layers of tabbing bond these bulkheads to the hull.

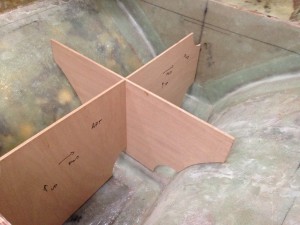

Big tanks require internal baffles, which prevent the contents of tank from sloshing violently in a heavy seaway. These tanks are low and amidships, which is where there is the least motion. Partitioning this tank into four units will be sufficient. The following photo shows the pattern for the athwartship baffle under construction.

The baffles were cut from 3/8″ Okume. The baffles must include openings that allow the tank contents to move from compartment to compartment.

The baffles that run fore-aft have a fairly simple shape, so the patterns are correspondingly simple.

The following photo shows the baffles dry-fitted in the tank.

As we have seen, the inspection port is very generous, and here we can see that there will be easy access to all points in the interior of the tank.

To strengthen the baffles (and as a first measure to seal them), they were covered on each side with biaxial fiberglass cloth.

Meanwhile, the pattern used to make to top of the forward tank was modified and then used to make the pattern for the top of the aft tank.

The aft tank has a different shape from the forward tank, which is evident from the shape of the top.

Meanwhile, the (new) compression posts that support the mast step were bolted to the coachroof, as shown in the following photos.

The following two photos were taken in a previous stage of the project. The first shows the forward compression post. The bottom of the post is screwed to the top of a long, wide, and tall block of wood. The second shows the block of wood after removal.

The original block of wood will not be used, and the following photo shows the space under the bottoms of the compression posts that must be filled. There is 11.5″ of clearance below the aft compression post and 7″ of clearance below the forward compression post.

The new block of wood will be made up of a lamination of white oak. The following photo shows the bottom piece of oak and we can see that there is an unacceptable gap between the “floor” and the wood.

The gap may be reduced either by building up the floor or shaping the wood. The floor is smooth, but not flat, and shaping the wood was the easier option. The wood was shaped using a combination of sanding and planing. The result was a much smaller gap, which will disappear by coating the bottom of the block with thickened epoxy before installation.

The white oak was 8/4 and about 6″ wide and 4′ long. (In woodworking terminology, X/4 wood is X/4″ thick before milling. Thus, 8/4 wood is 2″ thick, 6/4 is 1.5″ thick, and so on.) The following photo shows three pieces of oak that have been laminated together using thickened epoxy.

The following photo shows the new and old blocks of wood side by side. The new block is wider, and is made of denser, harder wood.

The next step will be to install the new block of wood, then build it up to the bottoms of the new compression posts.